Tips for Selecting Reliable PCB Assembly Services

In today’s rapidly evolving electronics industry, printed circuit boards (PCBs) are the backbone of virtually every modern device. From smartphones and automotive sensors to robotics and telecommunications equipment, PCBs make complex electronic functionality possible. Choosing the right PCB assembly service is a crucial step in ensuring performance, reliability, and long-term value. With so many suppliers in the market, knowing what to look for can save time, money, and future technical headaches.

Below are essential tips to help you select a reliable and technically proficient PCB assembly partner.

1. Evaluate Technical Capabilities and Manufacturing Expertise

When comparing PCB assembly providers, begin by assessing their technical capabilities. A trustworthy manufacturer should be able to handle diverse technologies and offer a wide range of services — from single- and double-layer boards to advanced Rigid-Flex and High Frequency PCBs.

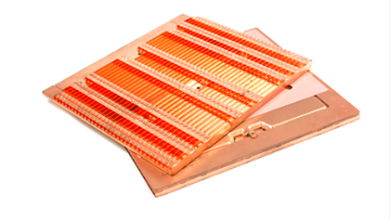

Rigid-Flex PCBs are especially valuable in modern electronics where compact designs, flexibility, and signal integrity are critical. Meanwhile, High Frequency PCBs are designed to perform at microwave and radio frequencies, making them essential for telecom and high-speed communication devices.

Working with a manufacturer that understands these technologies ensures that your project can evolve from prototype to mass production smoothly. For example, a Metal core PCB supplier such as Global Well PCBA offers specialized production for heat-dissipating applications like LED lighting and power converters.

2. Check Quality Certifications and Industry Standards

Reliable PCB assembly services adhere to international quality standards. Certifications such as ISO 9001, IATF 16949, and UL compliance demonstrate a company’s commitment to consistent quality and process control.

In addition, manufacturers that follow IPC-A-610 (Acceptability of Electronic Assemblies) ensure that every board meets professional inspection and soldering criteria. This minimizes the risk of defects and enhances long-term reliability — a crucial factor for mission-critical applications like aerospace, medical, and robotics.

Before committing to a supplier, verify their quality documentation and ensure they have an established inspection protocol at each stage of production.

3. Assess Production Scalability and Flexibility

Every project evolves — starting with prototypes and small test batches before scaling to full production. A dependable PCB assembly service should be equipped to manage both small and large-scale production runs without compromising lead time or quality.

Look for suppliers that provide end-to-end services, including component sourcing, PCB fabrication, assembly, and final testing. This level of vertical integration not only simplifies logistics but also ensures consistent quality control across the process.

Global Well PCBA, for example, is known for its capability to deliver small-batch prototypes as well as large-scale orders, giving customers flexibility at every development stage.

4. Review Component Sourcing and Supply Chain Management

Component quality directly impacts PCB reliability. The best assembly providers have robust supply chain management systems and established partnerships with reputable component distributors.

Ask about their sourcing practices — whether they use original, traceable components from authorized channels. Reputable manufacturers will avoid gray-market parts and offer complete transparency regarding component origin.

Furthermore, they should maintain a sufficient stock of critical components to mitigate risks from global shortages — a growing concern in today’s electronics industry. Efficient sourcing helps keep production schedules on track while maintaining performance consistency.

5. Examine Testing and Quality Assurance Processes

Testing is one of the most vital steps in PCB assembly. Reliable manufacturers will implement multiple testing stages to detect defects early and ensure the final product meets all functional requirements.

Common testing methods include:

Automated Optical Inspection (AOI) for surface defects and solder issues

In-Circuit Testing (ICT) for electrical performance validation

Functional Testing (FCT) to confirm real-world performance

X-ray Inspection for multilayer boards and BGAs

An experienced PCB assembly service provider should also offer custom testing solutions tailored to your product requirements. This proactive approach minimizes rework and improves long-term product stability.

6. Evaluate Communication and Technical Support

Transparent communication is a sign of a reliable business partner. A strong technical support team ensures that customers receive timely updates, clear quotations, and quick responses to design or production queries.

Ideally, your PCB partner should assign dedicated engineers or account managers who understand your product requirements in detail. Effective communication during the design for manufacturability (DFM) stage prevents costly design errors and reduces lead times.

Global Well PCBA, for instance, maintains an English-language interface and responsive customer service team, making it easy for international clients to communicate their technical needs effectively.

7. Compare Lead Times and Delivery Options

Lead time is a key performance indicator in PCB manufacturing. While competitive pricing is important, a short and predictable turnaround is equally crucial, especially for companies working on tight development schedules.

Reliable suppliers will provide transparent delivery timelines, keeping you informed of any potential delays due to material sourcing or production scheduling. Some also offer expedited production services for urgent projects.

Always request detailed production schedules and delivery estimates before placing an order to ensure alignment with your project milestones.

8. Look for Advanced Capabilities and Innovation

Innovation in PCB technology continues to evolve — with trends like HDI (High-Density Interconnect), metal core boards, and rigid-flex hybrids driving performance in cutting-edge applications.

Manufacturers who invest in new equipment, cleanroom facilities, and automated assembly lines demonstrate a commitment to staying ahead of industry standards. These innovations improve trace accuracy, solder quality, and overall yield rates.

Partnering with an experienced Metal core PCB supplier that utilizes state-of-the-art processes ensures your designs benefit from the latest advancements in electronic manufacturing.

9. Consider Industry Applications and Specialization

Every industry has unique requirements. Telecommunications equipment demands stable high-frequency performance; automotive electronics require vibration resistance; robotics depend on flexibility and compactness.

A PCB manufacturer with experience in multiple sectors can tailor its processes and materials to your specific needs. Whether it’s high-frequency communication systems or power-driven industrial robotics, choosing a manufacturer with relevant domain experience ensures optimal performance and durability.

Suppliers like Global Well PCBA provide customized solutions for various industries, balancing functionality, heat management, and mechanical strength.

10. Balance Cost with Long-Term Value

While cost is always a factor, the cheapest option is not always the most cost-effective. Low prices can sometimes mean compromised materials or limited quality control. Instead, focus on long-term reliability and consistent performance.

A well-manufactured PCB reduces maintenance costs, prevents device failures, and supports brand reputation. It’s wiser to invest in quality upfront rather than deal with expensive redesigns or product recalls later.

A reputable supplier provides competitive pricing without sacrificing technical excellence or after-sales support.

Conclusion

Selecting a reliable PCB assembly service requires a careful balance of technical evaluation, process transparency, and long-term partnership. By focusing on quality standards, production flexibility, component sourcing, and innovation, you can ensure that your electronic products perform consistently and efficiently.

Whether you need Rigid-Flex, High Frequency, or Metal Core PCBs, choosing a trusted partner like a professional Metal core PCB supplier ensures precision manufacturing, reliable delivery, and expert support throughout your product’s lifecycle.

A dependable PCB manufacturer isn’t just a vendor — it’s a vital part of your product development journey.